Prototype manufacture and production as one-off items or in small or large batches

If you require specific hydraulic components or component groups that are not available off the shelf, the HANSA‑FLEX prototype manufacturing teams are always pleased to help. We manufacture individual items to suit customer specifications, drawings or a sample, bring the prototype into first use, and, if required, advise and assist you with the product to reach series production readiness. With specialist knowledge, certifications and state-of-the-art machines, we create efficient solutions to meet every challenge.

Prototype manufacture, the complete process

Prototype manufacture with HANSA‑FLEX includes design, manufacture, quality control, bringing into first use and advice and assistance up to series production readiness.

Customised prototypes in line with customer specifications

If you require a hydraulic component or component group that is not available anywhere on the market, you do not need special technical knowledge or a drawing with HANSA‑FLEX. We take your individual requirements for the component or component group, design it and prepare the final drawing. We are able to implement your specific requirements with respect to functionality, dimensioning and weight precisely. Of course, we further develop the drawing jointly with you until we have the optimum solution for your project.

Manufacture and quality assurance and compliance with standards

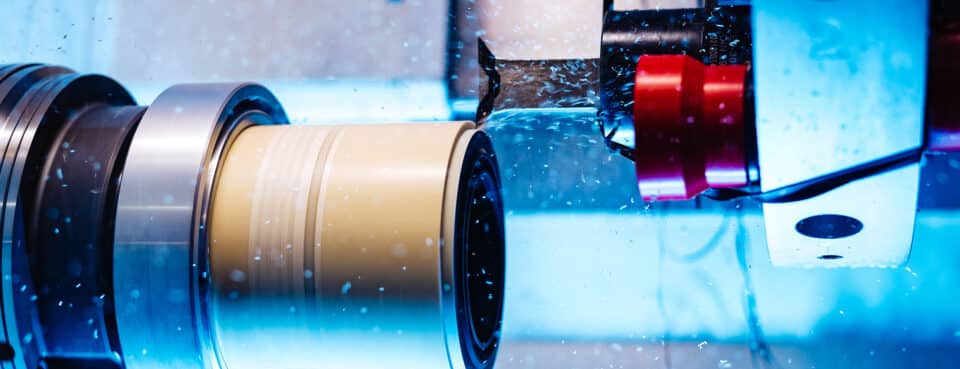

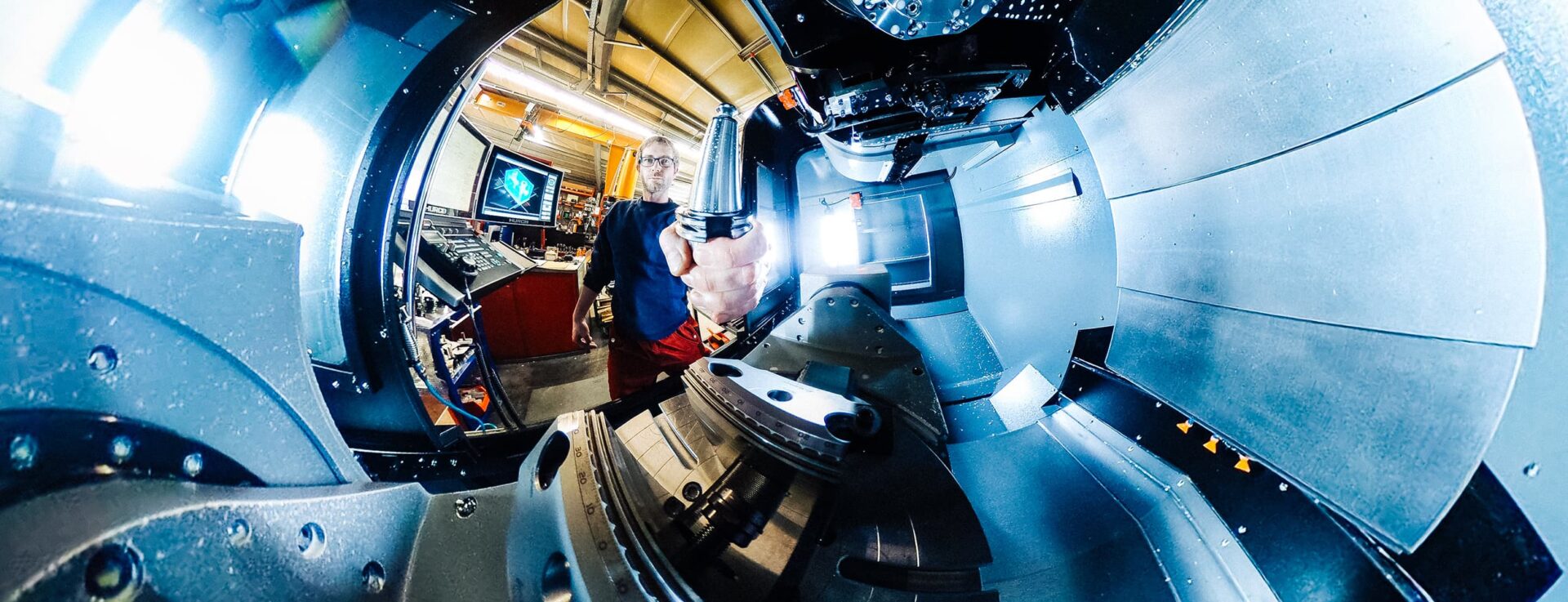

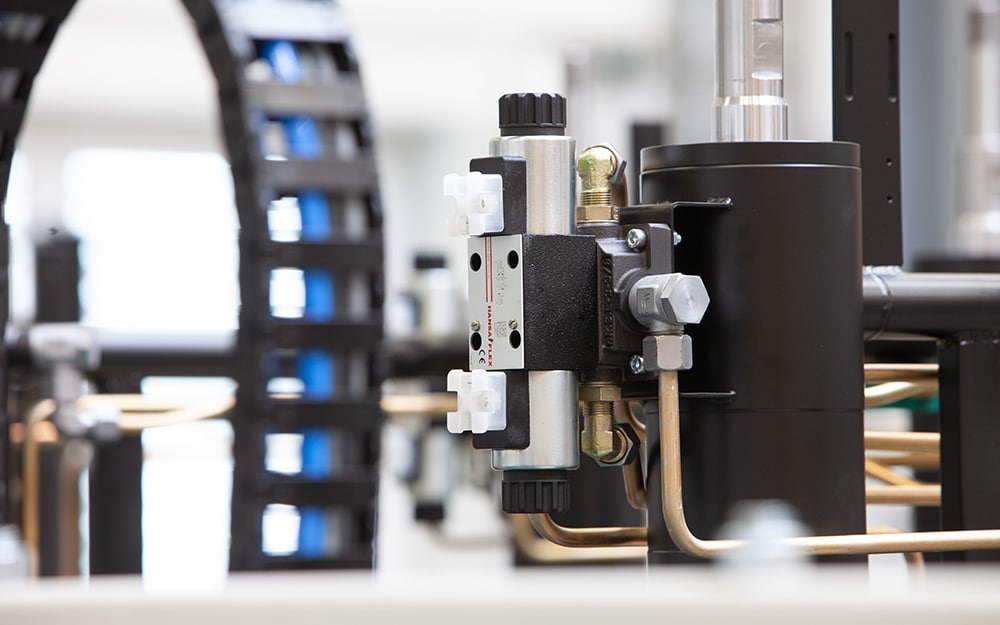

For the manufacture of prototypes, we draw on our comprehensive know-how, state-of-the-art production facilities, numerous certifications and our practice-proven quality management system.

- Manufacturing in accordance with all the relevant standards

- Precision parts produced in 5-axis machining centres

- Operatives certified for complex welding procedures

- Approvals for rail transport vehicles and maritime applications

- Extensive tests on our in-house test benches

Bringing into first use, advice and assistance up to series production

No prototype leaves our production facilities without undergoing a thorough individual approval process. If the prototype is to go into series production, we are there to advise and assist you all the way to series production readiness and can undertake its manufacture in-house at HANSA‑FLEX or at the premises of one of our expert partners.

- Bringing into first use in-house or at the customer’s premises

- Adjusting the components to the customer’s individual set-up requirements

- Small and large batch series production at attractive terms

Prototype manufacture using skills from different disciplines

For prototype manufacture, HANSA‑FLEX calls on its highly specialised hydraulic engineering teams.

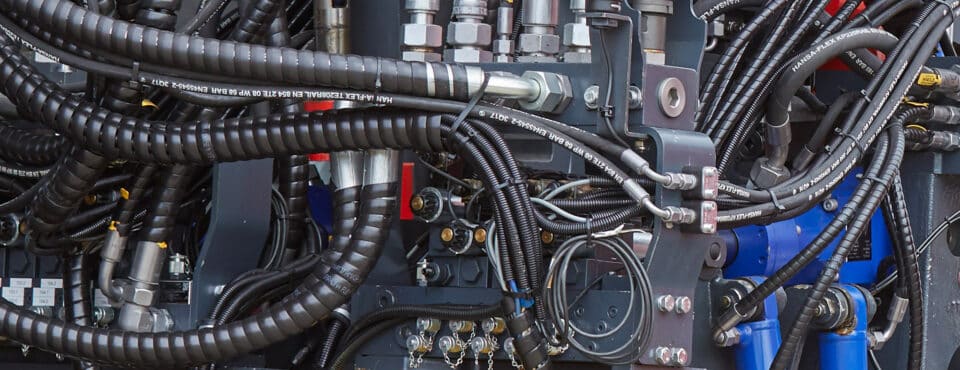

Prototype manufacturing in hydraulics generally involves expertise in numerous specialist areas of work. For many components in an individual component group to be made to match one another requires access to specialist competences in a wide range of disciplines. In order to manufacture prototypes, HANSA‑FLEX brings together competences in the fields of special fittings and metal working, comprehensive know-how of cylinder construction, sealing technology, power unit manufacture and in many other areas of expertise.

Your advantages with HANSA-FLEX prototype manufacture

Gain from our comprehensive hydraulics know-how in the design, planning and implementation of your project.

Specific specialist knowledge in all areas

HANSA‑FLEX has extensive experience in all disciplines of hydraulics.

Individually made to the customer’s wishes

We are completely familiar with the process of prototype manufacture and implement your wishes.

Compliant with standards and certified

We manufacture using certified employees and in accordance with all relevant standards

Advice and assistance right up to series production

We manufacture products as one off items or in small or large batch series production.

Prototype manufacture to suit the customer’s need

Prototype manufacture at HANSA‑FLEX begins with consultation without condescension between equal partners, which results in a product that fulfils the highest functional and quality standards in the desired application.

You may also be interested in this

Hydraulic hoses

Hydraulic hoses transfer fluid safely through the system. Their flexibility means they need very little installation space. The HANSA‑FLEX range includes elastomeric…

Find out morePipelines

The HANSA‑FLEX range of pipeline products includes expansion joints, bent pipes and special fittings for liquids, gases and coolant water. HANSA‑FLEX’s state-of-the-art manufacturing…

Find out moreSealing technology

Hydraulic and pneumatic systems are only as good as their seals. Just one defective seal can lead to long downtimes…

Find out more