Measuring technology for hydraulic systems from hansa‑flex

Measuring technology in hydraulic systems must be highly precise. Pressure, temperature and volumetric flow need to be measured accurately to ensure systems and machines operate reliably. Continuous condition monitoring can be an effective way to prevent wear on hydraulic components. Digital measuring instruments are becoming increasingly popular for the control and regulation of automatic processes.

Analogue and digital measuring technology

Our online shop offers proven measuring technology and innovative measuring systems from renowned manufacturers for various fields of application. Our experts advise you on the choice and design of measuring devices, sensors and evaluation software.

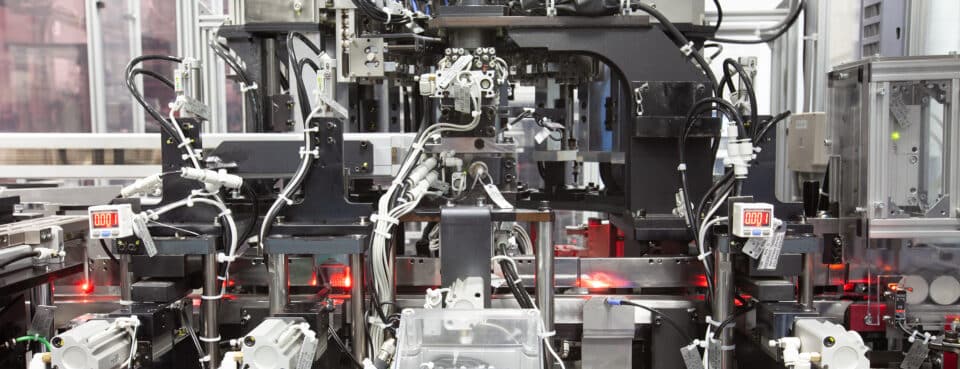

Digital measuring technology

Digital measuring technology comes into its own when very exact measurements are needed or measurement data are to be recorded over longer time periods. This technology makes use of sensors to clearly evaluate any situation.

- Digital 2- and 5-channel manual measuring device

- Digital pressure, temperature and rotational speed sensors

- Associated accessories such as measuring cables

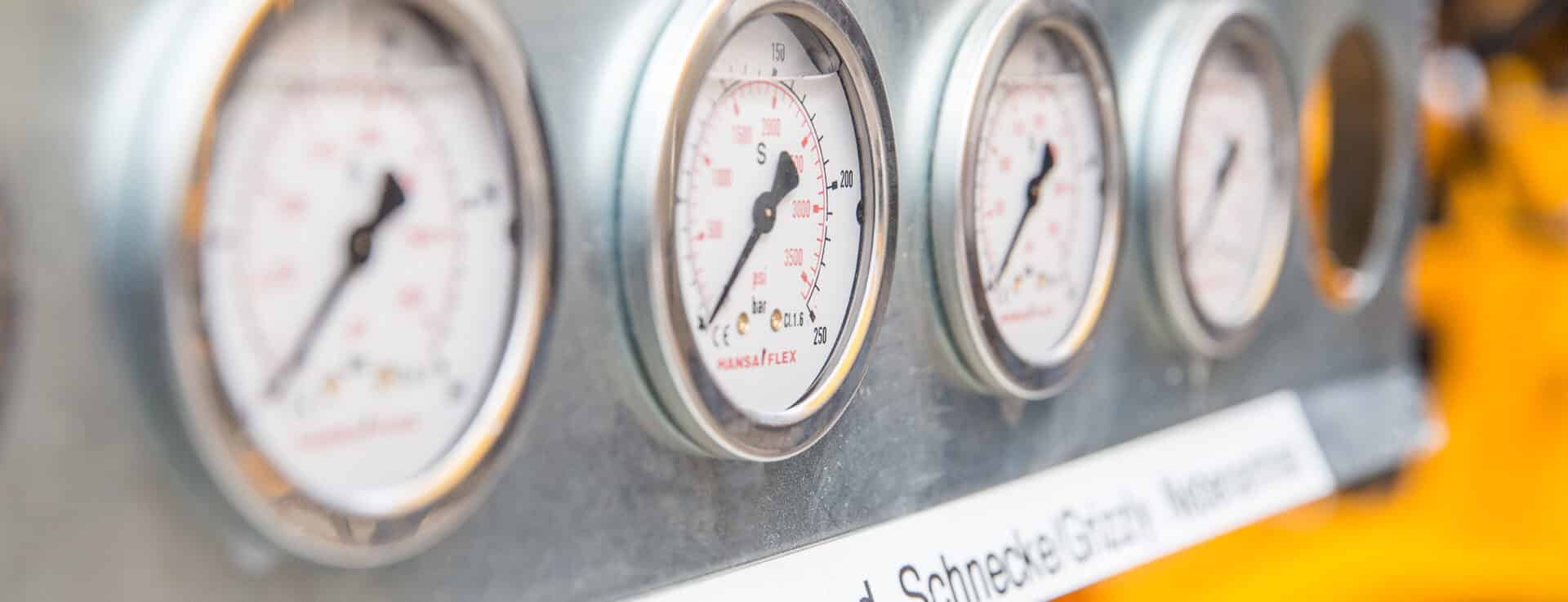

Analogue measuring technology

Not all measurements have to be accurate to three decimal places. In these cases, analogue measuring technology is a good choice. These devices are cost-effective and supply reliable measurement data.

- Gauges with front ring and clamping ring mountings

- Flow monitors, volume flow meters and flow meters

- Accessories such as measuring hoses, fittings and shut-off valves

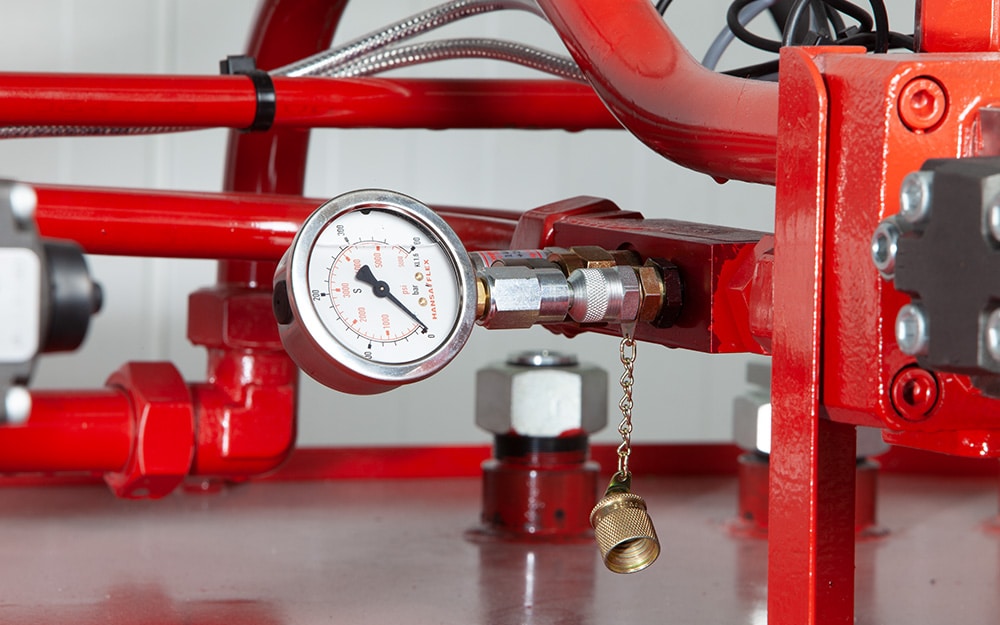

Measuring connections, couplings and fittings

Measuring connections and fittings allow measuring points to be installed in the hydraulic system. Couplings allow quick and easy connection of components during diagnosis and servicing.

- Measuring connections M16x2, M16x1.5 and S12.65x1.5

- Flat-seal couplings for diagnosis and servicing applications

- Clamping ring fittings in steel and stainless steel

Purchase measuring technology from the fluid specialists

Precise measuring technology supplied by HANSA‑FLEX forms the basis for monitoring, controlling and optimising the operation of hydraulic systems.

Comprehensive product range

Measuring devices and analysis systems for pressure, flow and temperature measurement

Best quality

Extensively tested products with international approvals for the highest precision

Customer-specific solutions

Supplier of analogue and digital measuring systems to suit customer-specific requirements

Support from experts

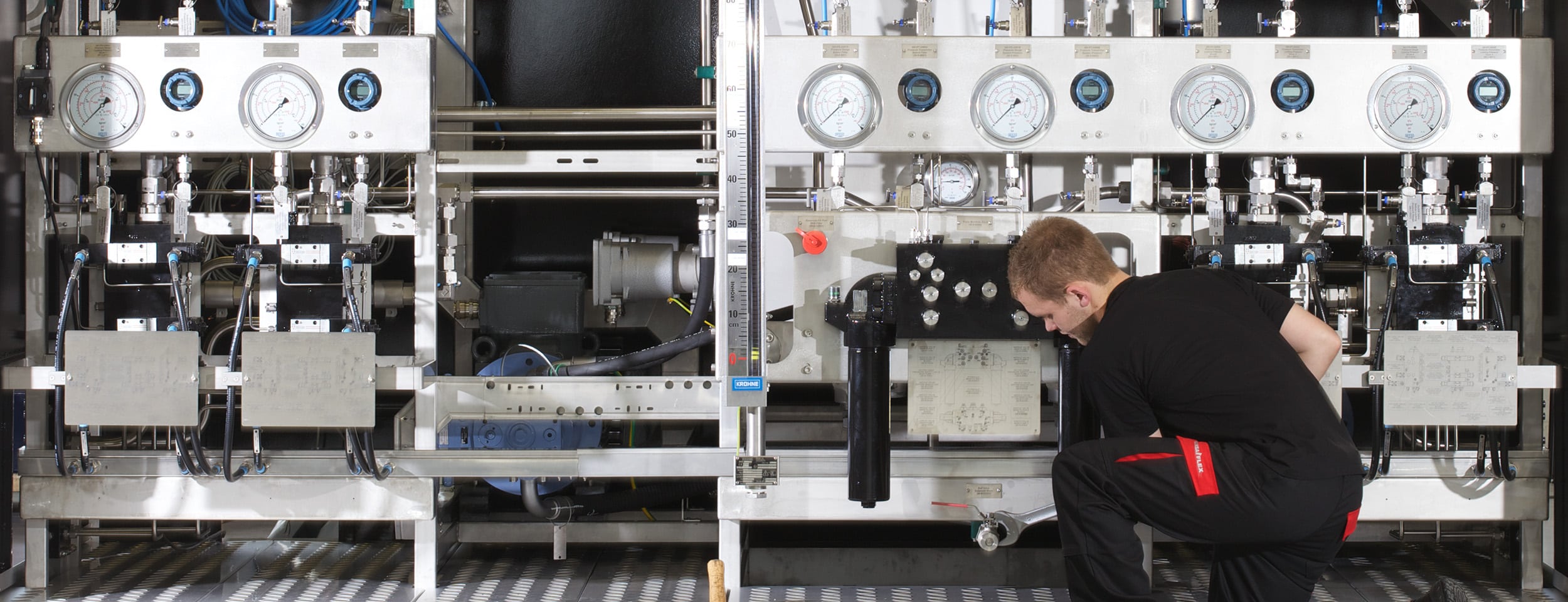

Selection and installation of the measuring technology and condition monitoring of hydraulic systems

Hansa‑flex has a comprehensive and proven measuring technology po

Our product portfolio includes systems for reliable particle measurement, flow meters, volume flow measuring devices, pressure gauges, connections, hoses and measuring couplings.

- Digital and analogue measuring devices

- Mobile and fixed measuring systems

- Analogue/optical and electronic evaluation options

- Recording and control of pressure, temperature and volumetric flow

- For system monitoring and improvement of plant efficiency

Measuring technology for recording pressure, volumetric flow and temperature

- Pressure

- Volume

- Temperature

- Item 1

Pressure measuring devices for all areas of use

Pressure monitoring in hydraulic systems is essential for machines and equipment to operate smoothly and reliably. As well as simple gauges for measuring pressure, HANSA‑FLEX also supplies pressure sensors for highly precise measuring equipment for incorporation into electrical controls.

- Allowable working pressure: Up to 600 bar

- Measuring accuracy: +/- 0.5 % of full scale

- Measuring ranges of our pressure sensors: 0 to 10 bar and 0 up to 600 bar

- Item 1

Volume flow meters from HANSA‑FLEX

Volume flow meters measure the volume of oil flowing per unit of time. HANSA‑FLEX supplies volume flow meters, flow monitors, turbine flow and gear flow meters.

- Measured volume: Up to 600 l per minute

- Measuring accuracy: +/- 0.5% of reading

- Measuring ranges: 1 to 20 l/min and 40 up to 600 l/min

- Item 1

Reliable temperature measuring devices

Simple temperature measuring devices such as thermometers or pressure-resistant sensors measure the temperature of the oil in hydraulic systems, in the tank or at separate measuring points. They also allow the user to monitor fluid quality, because temperatures of over 60 °C lead to premature ageing of hydraulic oil and have detrimental effects on viscosity.

- Temperature measurement with electronic sensors

- Permissible highest temperature: 200 °C

- Measuring accuracy: +/- 2 Kelvin

Ready-to-install measuring technology sets in a practical transport case

Our online shop offers you complete measuring and analysis systems in addition to ready-to-use sets including sensors, connections, hoses and measuring cables in a robust transport case. We are also happy to configure customised measuring technology sets for your specific requirements.

- Analogue measuring device sets

- Digital measuring device sets

- For use during servicing and for long-term measurements

What everyone should know about hydraulic measuring technology

What advantages are there with glycerine-damped gauges for pressure measurement, what does measurement accuracy refer to and how does a gear flow meter work? Our experts explain.

These topics may also be of interest to you

Pneumatics

Pneumatics are at the heart of automated processes in logistics centres, small parts warehouses and the automotive industry. Compressed air…

Find out moreAssembly and installation

Our excellently trained service technicians carry out assembly and installation work on hydraulic systems. Irrespective of whether the work involves…

Find out moreHydraulic connection technology

Hydraulic connecting elements, such as adapters, fittings and threaded connectors, are an essential means of joining components in hydraulic systems.…

Find out more